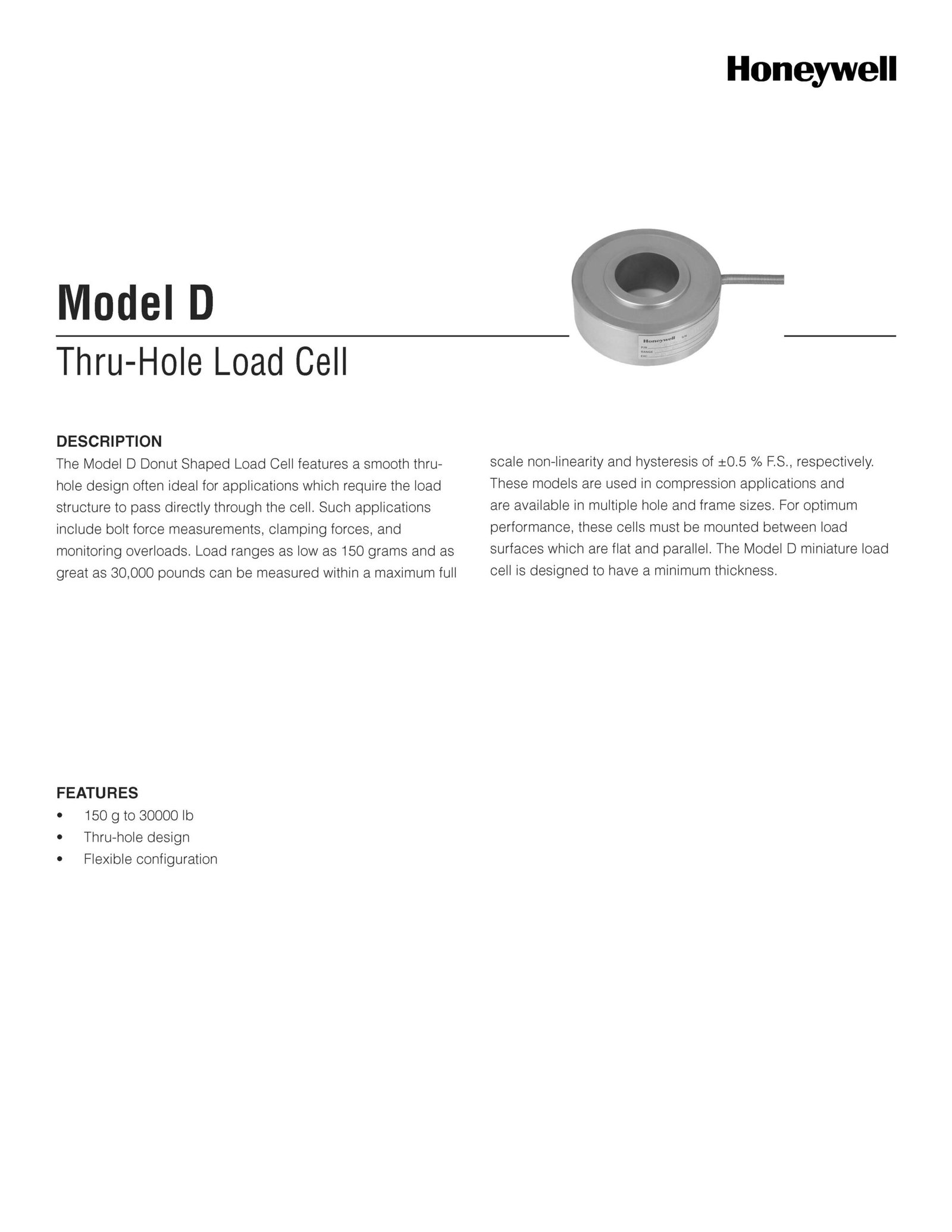

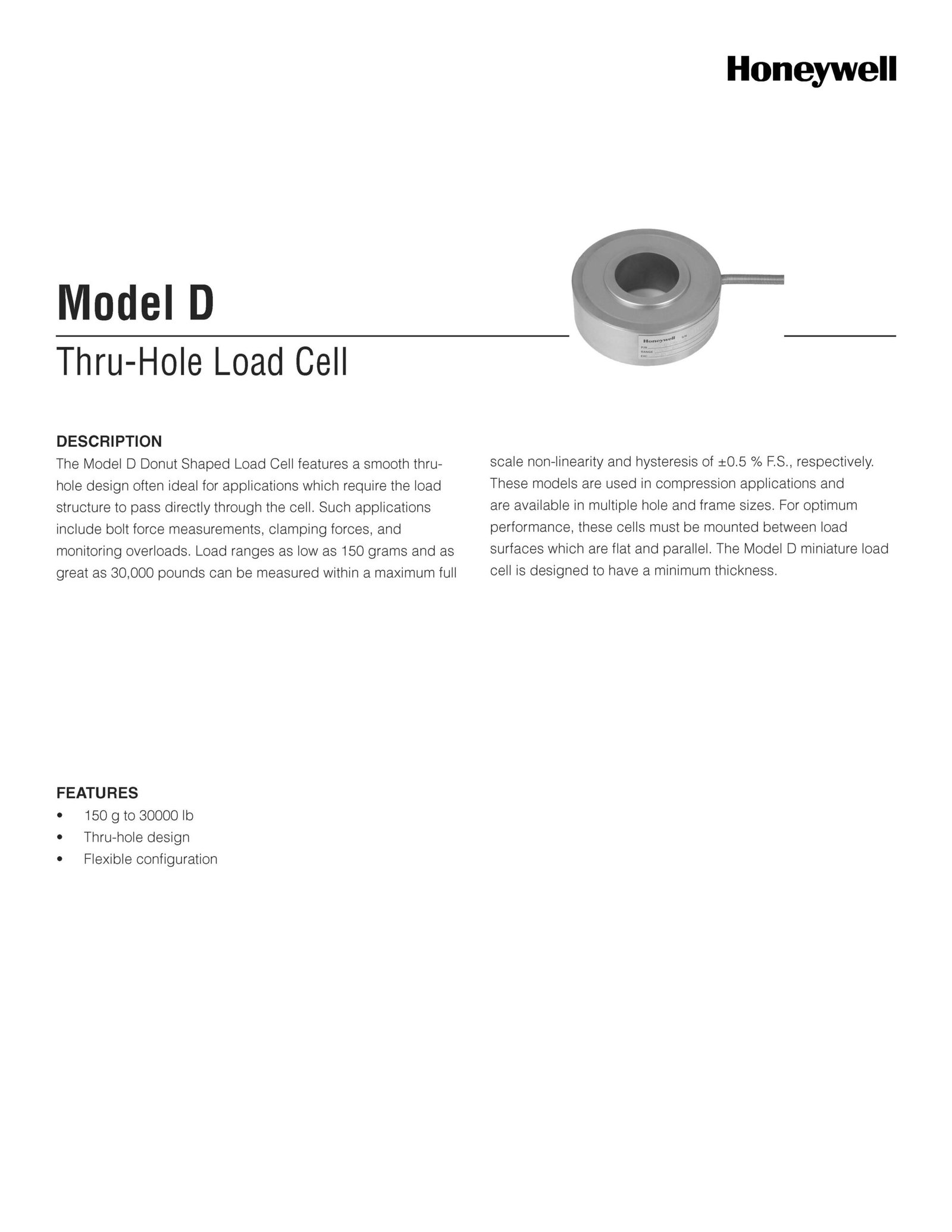

Honeywell Model D Thru-Hole Load Cell

케이센서스 스마트스토어

케이센서스 스마트스토어

The Model D Donut Shaped Load Cell features a smooth thru-hole design often ideal for applications which require the load structure to pass directly through the cell. Such applications include bolt force measurements, clamping forces, and monitoring overloads. Load ranges as low as 150 grams and as great as 30,000 pounds can be measured within a maximum full scale non-linearity and hysteresis of ±0.5 % F.S., respectively. These models are used in compression applications and are available in multiple hole and frame sizes. For optimum performance, these cells must be mounted between load surfaces which are flat and parallel. The Model D miniature load cell is designed to have a minimum thickness.

The Model RGF In-Line load cells are high quality, stainless steel rugged load cells capable of withstanding significant off-axis loads, making them an ideal choice for in-line compression measurement or tension measurement where side loading cannot be completely controlled. The flexible mounting options make applications easier to implement, and the all stainless steel, hermetic construction is well suited to corrosive and very high humidity environments.

Model AL-JP is a high output load cell (30 mV/V minimum). These semiconductor strain gage load cells are engineered to measure loads from 500 lb to 2000 lb. The tension/compression Model AL-JP is designed with female threads. It provides high performance in non-linearity, hysteresis, and repeatability. Low mechanical deflection allows for better response capability.

The Model 3127 fatigue-resistant load cells are extremely resistant to extraneous bending and side loading forces. The structure virtually eliminates bending strains at the strain gage, minimizing the primary cause of load cell failure. Dual bridge option available for feedback control and redundancy.

The Model LC digital force indicator is a highly portable force measurement device. With its 9 V battery supply and compact size the indicator can easily be carried to remote locations to perform force measurement calibrations. The unit can measure compression forces up to 50,000 lbs.

The peak capture feature allows the highest force reading taken to be displayed with the push of a button. The remote location of the load sensor minimizes the chance of damage to the electronic body of the gauge. The stainless steel construction of the sensor and the indicator makes them often resistant to the occasional mishandling than can occur in the field. Optional handles are available for the load cell and gauge.

Each unit has a membrane face with raised buttons and tactile feedback for setup and operation. The high, low, and clear buttons are easily accessible on this front membrane. Zero adjustment and zero offset/tare functions are standard on each unit. Calibration and setup parameters are stored on a memory chip to protect from loss even when power is interrupted. Unauthorized set ups and calibrations are also blocked with internal security. Various combinations of the front panel buttons can be de-activated.

The Model RGH In-Line load cells are high quality, stainless steel, rugged load cells capable of withstanding significant off-axis loads, making them an ideal choice for in-line compression measurement or tension measurement where side loading cannot be completely controlled. The flexible mounting options make applications easier to implement, and the all stainless steel, hermetic construction is well suited to corrosive and very high humidity environments.

The small-diameter, cost-efficient load cells are designed to be used in applications that require an ability to mount in an existing system with restricted working area. They are commonly used in fluid power transfer systems. Their low cost and ease of mounting allow simultaneous testing of multi-element systems.

They may be directly attached to the piston rod of a hydraulic cylinder. Side-mounted cable connectors allow cable assemblies to be supported without affecting movement of the cell during tension or compression loading.

The Model RGM In-Line load cells are high quality, stainless steel, rugged load cells capable of withstanding significant off-axis loads, making them an ideal choice for in-line compression measurement or tension measurement where side loading cannot be completely controlled. The flexible mounting options make applications easier to implement, and the all stainless steel, hermetic construction is well suited to corrosive and very high humidity environments.

The Model 127 load cells combines both a compact form and high precision to offer a superior tension force transducer. The one-piece S-shaped design achieves a maximum non-linearity of 0.03 % full scale for load ranges of 50 kg and 100 kg.

The pedal pressure sensor mounts directly to the brake pedal with its own mounting clamp. Load applied up to 1/2 inch off center, produces less than a 0.5% error. Standard capacity is 300 lbs. This load cell, which is used for brake pedal force measurements by the automotive industry, finds many production applications. It adapts to any of the pedal or bar operated devices used in all production facilities.

WhatsApp us