Honeywell Model AL-JP High Output Load Cell

케이센서스 스마트스토어

케이센서스 스마트스토어

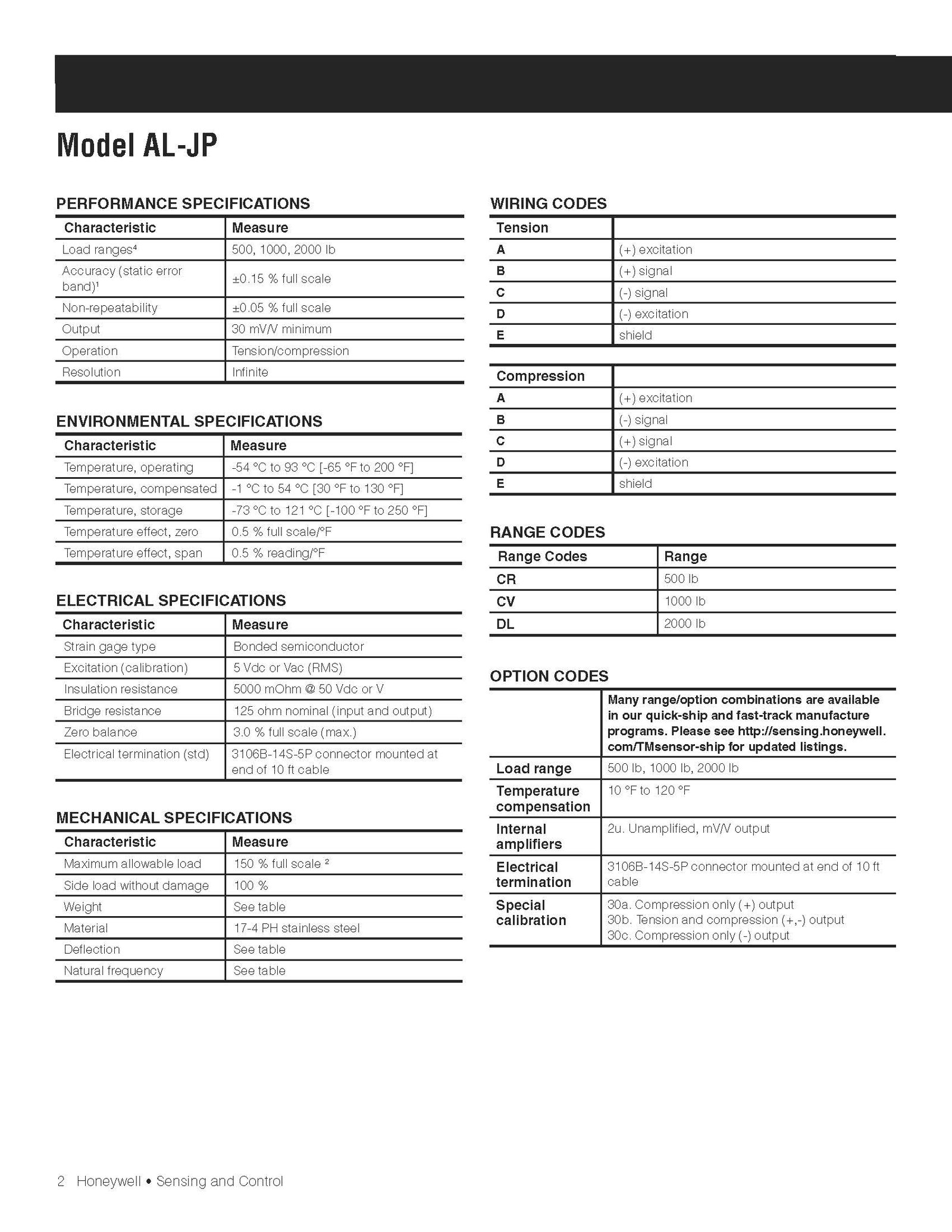

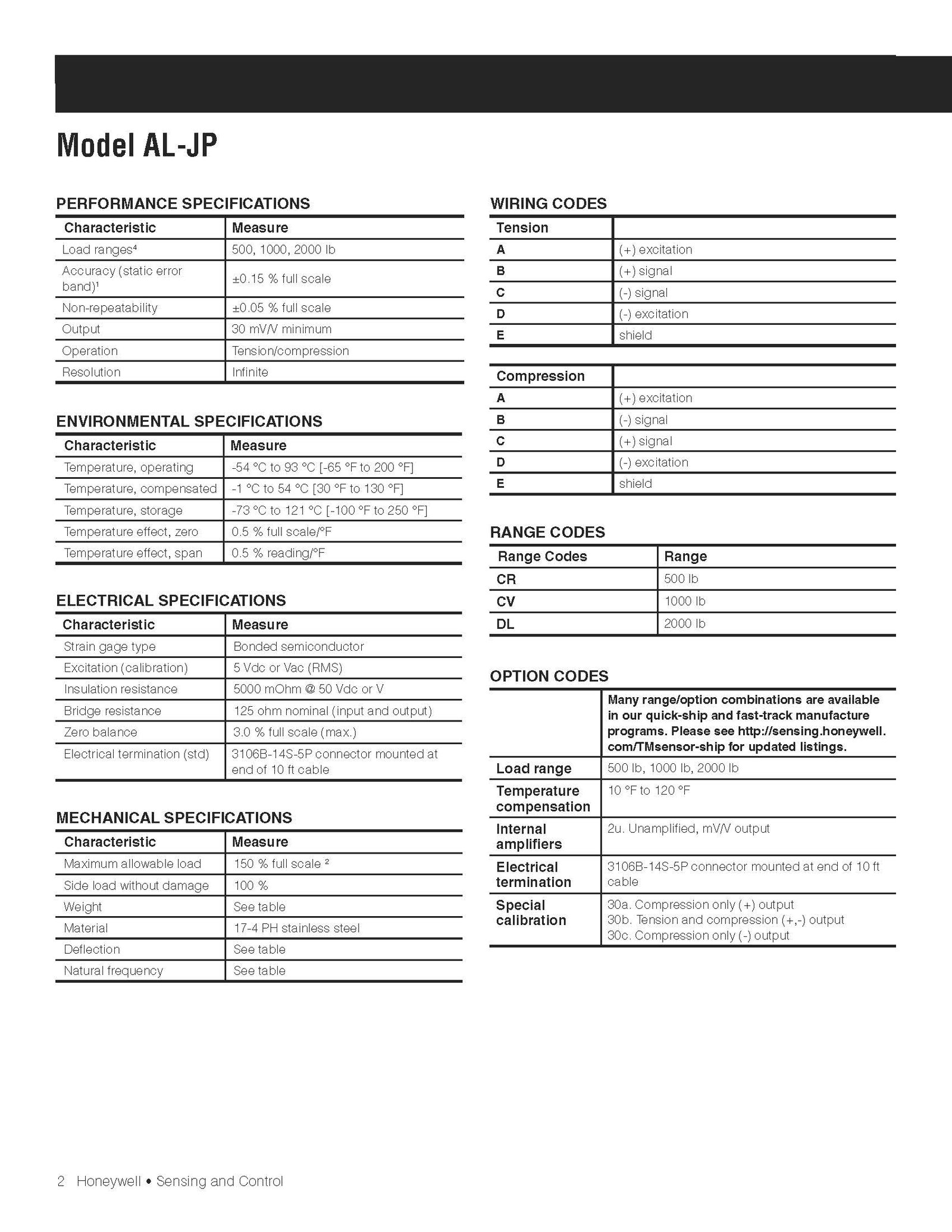

Model AL-JP is a high output load cell (30 mV/V minimum). These semiconductor strain gage load cells are engineered to measure loads from 500 lb to 2000 lb. The tension/compression Model AL-JP is designed with female threads. It provides high performance in non-linearity, hysteresis, and repeatability. Low mechanical deflection allows for better response capability.

Model 13 (compression only) subminiature load cell is designed to measure load ranges from 150 g to 1000 lb. With subminiature dimensions, including diameters from 0.38 in to 0.75 in and heights of 0.13 in to 0.25 in, these units are easily incorporated into systems having limited space. Model 13 combines high frequency response and low deflection to achieve a combined non-linearity and hysteresis of 0.25 % to 0.5 % full scale. A balance module is included in the load cell’s lead wire cable for temperature compensation and should not be removed.

The Model 3129-121 fatigue-resistant load cells are extremely resistant to extraneous bending and side loading forces. The structure virtually eliminates bending strains at the strain gage, minimizing the primary cause of load cell failure. Dual bridge option available for feedback control and redundancy.

Honeywell’s cost-effective, general purpose, carbon steel, pancake load cells offer a compact design that features exceptional structural capability to withstand extraneous loads, such as torque, bending movements and side loads combined with a high degree of accuracy for general purpose applications.

Designed to measure tension/compression, these load cells have enhanced accuracies up to 0.07 % and have measurement ranges from 5 lb up to 100,000 lb. Fatigue-resistant and fatigue-rated models for use with applications with extremely high cycle counts are available. Need special modifications or a custom design? Call us to discuss your requirements.

The Model 3127 fatigue-resistant load cells are extremely resistant to extraneous bending and side loading forces. The structure virtually eliminates bending strains at the strain gage, minimizing the primary cause of load cell failure. Dual bridge option available for feedback control and redundancy.

The Model 3130-131 fatigue-resistant load cells are extremely resistant to extraneous bending and side loading forces. The structure virtually eliminates bending strains at the strain gage, minimizing the primary cause of load cell failure. Dual bridge option available for feedback control and redundancy.

Model 34 precision miniature load cells measure both tension and compression load forces of 1000 g to 1000 lb. These models are our highest accuracy, rugged miniature load cells. Model 34’s welded, stainless steel construction is designed to eliminate or reduce to a minimum, the effects of off-axis loads. (The internal construction assures excellent long-term stability for ranges 1000 grams and above.) A modification permits this model to be completely welded for underwater applications. The Model 34 tension/compression load cell has female threads attachments. High accuracies of 0.15 % to 0.25 % full scale are achieved. Each bonded strain gage unit is built of welded 17-4 PH stainless steel for additional ruggedness. All load cells with ranges from 1 kg to 10 lb have an electrical balance module in the lead wire (approximately 1 in x .087 in thick). This balance module does not have to be the same temperature as the transducer.

Model 53 load cells are bonded foil strain gage transducers designed for cost efficient production and testing applications (i.e. press calibration). Engineered compression force measurements up to 50K lb., this model achieves a maximum non-linearity of 0.5 % full scale. Precision gaging techniques and a stainless steel construction provides excellent long-term stability and reliability under severe operating conditions. The Model 53 compression-only load cell has an integral load button machined as part of the load cell. The Model 53 must be mounted on a smooth flat surface for proper operation. Three tapped holes are provided for mounting.

The Model RGH In-Line load cells are high quality, stainless steel, rugged load cells capable of withstanding significant off-axis loads, making them an ideal choice for in-line compression measurement or tension measurement where side loading cannot be completely controlled. The flexible mounting options make applications easier to implement, and the all stainless steel, hermetic construction is well suited to corrosive and very high humidity environments.

The small-diameter, cost-efficient load cells are designed to be used in applications that require an ability to mount in an existing system with restricted working area. They are commonly used in fluid power transfer systems. Their low cost and ease of mounting allow simultaneous testing of multi-element systems.

They may be directly attached to the piston rod of a hydraulic cylinder. Side-mounted cable connectors allow cable assemblies to be supported without affecting movement of the cell during tension or compression loading.

These general purpose designs have exceptional structural capability to withstand extraneous loads, such as torque, bending moments, and side loads. Available in capacities of 25 lb to 300 lb, they offer maximum performance and enhanced accuracy. Minimum deflection and compactness make these general-purpose load cells easy to install and use.

WhatsApp us